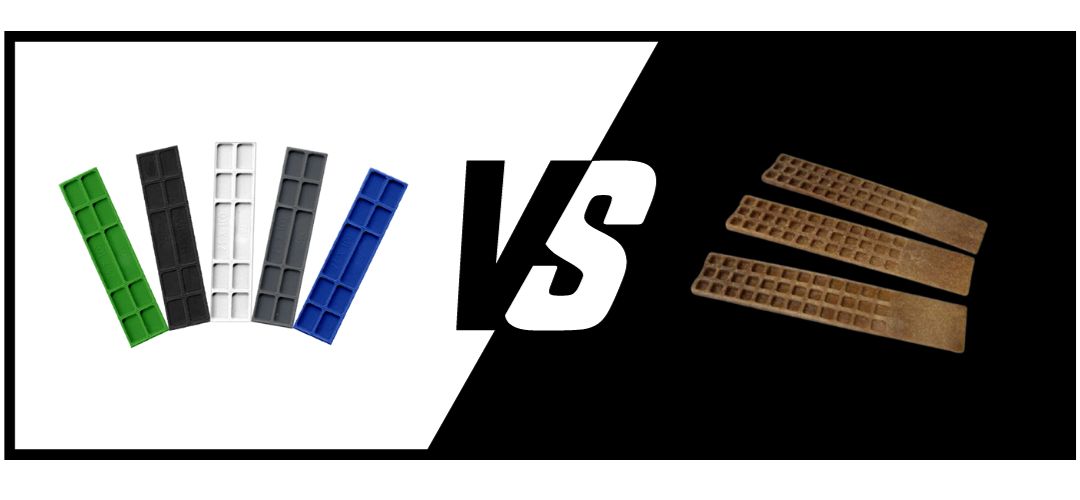

Shims play a pivotal role in ensuring stability and alignment within the construction industry. The ongoing debate regarding the advantages of plastic shims versus their traditional counterparts continues to influence decision-making processes among professionals. Alongside this debate, the expanded and innovative applications of both plastic and traditional shims in various construction scenarios have redefined their roles in modern building practices.

Understanding Plastic Shims:

Plastic shims, available from suppliers such as Packers Direct, have garnered recognition for their adaptability and durability. Crafted from high-quality materials, these shims offer impressive load-bearing capacity and resilience against moisture and temperature variations.

Advantages of Plastic Shims:

Plastic shims exhibit several advantages that have made them indispensable in modern construction practices:

- Enhanced Versatility and Customization: Plastic shims present an unparalleled level of adaptability in construction applications. Their diverse range of sizes, shapes, and thicknesses allows for precise adjustments and accommodations to various building materials and structural needs. This versatility makes them suitable for intricate designs and complex architectural projects, offering a level of customization not easily achievable with traditional shims.

- Uniform and Consistent Support: Precision-cut plastic shims offer uniform support across surfaces due to their standardized manufacturing processes. Their identical nature ensures even weight distribution and structural integrity, minimizing stress points throughout the construction process.

- Moisture and Chemical Resistance: Resistant to moisture and chemicals, plastic shims outshine traditional wood shims that are susceptible to decay from moisture absorption. This resistance makes plastic shims ideal for outdoor applications and in humidity-prone areas, ensuring stability and durability in adverse weather conditions.

- Durable and Long-Lasting Performance: Plastic shims are designed for extended durability, maintaining structural integrity over time. Their resistance to compression and degradation makes them suitable for long-term support in constructions such as bridges and high-rise buildings.

- Environmental and Sustainable Attributes: Many plastic shims are manufactured using recycled materials, contributing to sustainable construction practices. Their reusability and recyclability align with environmentally responsible building practices, reducing construction waste and promoting eco-friendly building solutions.

Exploring Traditional Shims:

Traditional shims, typically made from wood or metal, have long been the standard in construction practices. Though sturdy, they possess limitations, such as susceptibility to decay due to moisture.

Suppliers like Packers Direct offer a range of traditional shims crafted from high-grade materials, providing robust support across various construction applications.

Comparative Analysis:

The expanded applications of both plastic and traditional shims in modern construction practices have significantly redefined their roles in diverse construction scenarios, offering unique advantages and considerations.

- In High-Rise Construction:In high-rise projects, traditional shims have been the go-to choice for their robust support and alignment capabilities. However, the evolving landscape of construction demands has highlighted the limitations in intricate designs and adaptability. Plastic shims, with their enhanced versatility, uniform support, and resistance to environmental elements, present a compelling alternative. They offer precise alignment in complex building designs, ensuring stability, and addressing the challenge of adapting to dynamic architectural configurations. While traditional shims offer reliability in load-bearing capacities, plastic shims complement these strengths by addressing the demands of modern high-rise architecture with their adaptability and resilience.

- Within Glazing Systems:Glazing systems require reliable support for securing glass panels, necessitating weatherproofing capabilities. Traditional shims, while effective in certain scenarios, might lack the crucial weather-resistant qualities essential for glazing systems, making them susceptible to deterioration over time. Plastic shims, with their superior support and weatherproofing attributes, prove to be the optimal choice. Their resistance to moisture and uniform support ensures prolonged durability in glazing systems, addressing the challenge of maintaining structural integrity amidst varying weather conditions.

- Infrastructure and Bridge Construction:Bridge and infrastructure projects demand sturdy support to withstand heavy loads and environmental factors. While traditional shims offer established load-bearing capacities, their vulnerability to environmental elements might limit long-term reliability. Plastic shims demonstrate resilience against environmental factors, showcasing their potential for sustained support in such projects. Their resistance to moisture and degradation makes them a suitable choice for ensuring lasting stability in infrastructure projects, catering to the evolving demands of sustainable and long-lasting constructions.

- Interior Design and Sustainable Practices:Interior designs rely on stability and sustainability. Traditional shims, with their robust support, have been integrated into interior design elements. However, their limitations in terms of resistance to moisture or chemical exposure might restrict their utility in achieving sustainable interior design practices. Plastic shims, with their sustainable attributes, precise alignment, and resistance to environmental elements, offer a viable choice for eco-friendly and durable fixtures. They present an ideal solution for interior elements requiring lasting stability, aligning with the growing emphasis on sustainable design practices.

- Support for Sustainable Construction:Sustainable construction practices prioritize environmentally friendly solutions to reduce waste. Plastic shims significantly contribute to this objective. Manufactured using recycled materials, they ensure reusability and recyclability, promoting eco-friendly practices and contributing to waste reduction. While traditional shims offer reliability in certain construction aspects, they might not align as seamlessly with sustainability practices due to material limitations.

The comparative analysis of plastic and traditional shims across various construction applications underscores their unique advantages, highlighting their diverse capabilities and potential limitations in different scenarios. This comprehensive understanding aids in making informed decisions, ensuring the appropriate selection of shims for specific construction needs. Their expanded applications and specialized attributes redefine their roles in modern construction practices, offering solutions to the dynamic demands of diverse construction projects.

Craftsmanship Meets Global Standards

Unlock Precision with ISO-Certified Excellence! Explore our Premium Range of Shims, Packers, and Plastic Moulding Today.